PRECISION MANUFACTURING MADE EASY

The advanced manufacturing tools within Carveco™ software aid in preparing your designs for a variety of precision manufacturing methods. From routing wood, creating molds or press tools, laser cutting, engraving hard-wearing metals for production lines, or simply nesting your designs to achieve the minimum amount of material waste, Carveco affords the necessary control to ensure your designs can be manufactured to your exact specifications.

KEY FEATURES

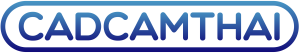

Relief Analysis

Carveco™ software includes relief-analysis tools which overlay colour information indicating both heights and gradients across your design. This is particularly beneficial in the creating of foiling and embossing dies, where height or angle thresholds are critical to the manufacturing process.

Tool Database

Use the fully editable Tool Database to manage your cutting tools and their associated parameters. Select the appropriate tool for your material type, or add your own specialized cutting bits to suit your tooling requirements.

Multi-Axis Machining

Your designs can be machined using 3-axis, or rotary 4-axis with automatic support for tool changing and rotary index moves. Alternatively, export a triangle or quadrangle mesh for use in additional manufacturing environments or alternative CAD/CAM programs.

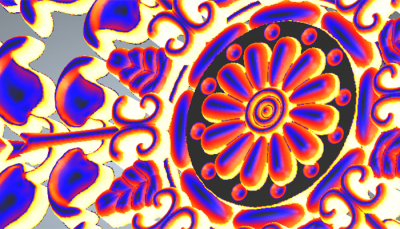

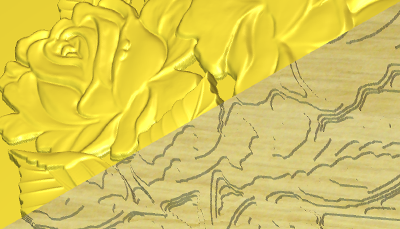

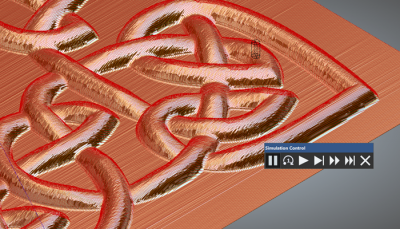

Machining Simulation

Carveco’s machining simulation allows you to preview the results of your tooling choices before committing time or sacrificing materials. Choose to simulate the entire design or a specific area of your model using the tools you’ve chosen, and render the results in a variety of realistic materials.

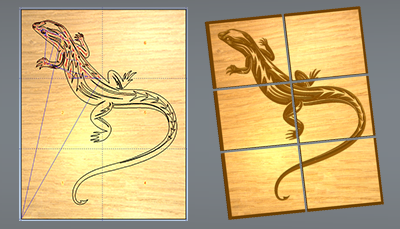

Toolpath Panelling

Produce designs beyond the constraints of your CNC bed or stock material by machining your design in calculated sections. Reposition your material as you work, or reassemble your cut sections at the end.

Projects & Assemblies

Carveco’s projects and assembly modelling tools enable you to build a complete 3D model of your work by combining imported 3D models and reliefs. Full positional controls let you easily orientate and position all elements prior to production.

Complete Toolpath Control

Carveco’s toolpath operations have been designed for tool room efficiency. See exactly how long your designs will take to machine with the Toolpath Summary. For repeat machining, save-out frequently used tool selections and strategies as a Toolpath Template. Transform, Copy and Merge your toolpaths together to streamline your production process.

2D MACHINING: STRATEGIES & FEATURES

Profile Toolpath

Machine along, inside or outside a boundary vector

Area Clearance Toolpath

Remove large amounts of material quickly

Bevel Carving Toolpath

Produces a bevelled edge carving along a vector

V-Bit Carving Toolpath

Create V-Bit recessed cuts along vectors

Inlay Toolpath

Machine corresponding male and female inserts

Fluting Toolpath

Create and control ramping cuts along defined vectors

Smart Engraving

Corner sharpening and speciality embossed effects

Texture Toolpath

Create textures using tool geometry

Raised Round Toolpath

Machine recessed letters and shapes with precision

Drilling Toolpath

Drill holes using selected vectors

2D Machining Wizard

Automated 2D machining and nesting

Drill Bank Toolpath

Support for multi-drill CNC machines and patterns

3D MACHINING: STRATEGIES & FEATURES

Machine Relief Toolpath

Machine a composite 3D relief

Feature Machining Toolpath

Centreline Engraved, Raised or Recessed features

Z-Level Roughing Toolpath

Rough out 3D material from your composite relief

3D Profile Toolpath

Cut out your 3D model with a profiling toolpath

Laser Machining Toolpath

Dedicated toolpaths for Laser Engraving CNC machines

3D Rest Machining Toolpath

Machine-away material larger tools cannot reach

3D DESIGN FOR

ARTISTIC ENGINEER…